Control Systems

2024

PLC Logic Optimization & HMI Revamp for Production Lines

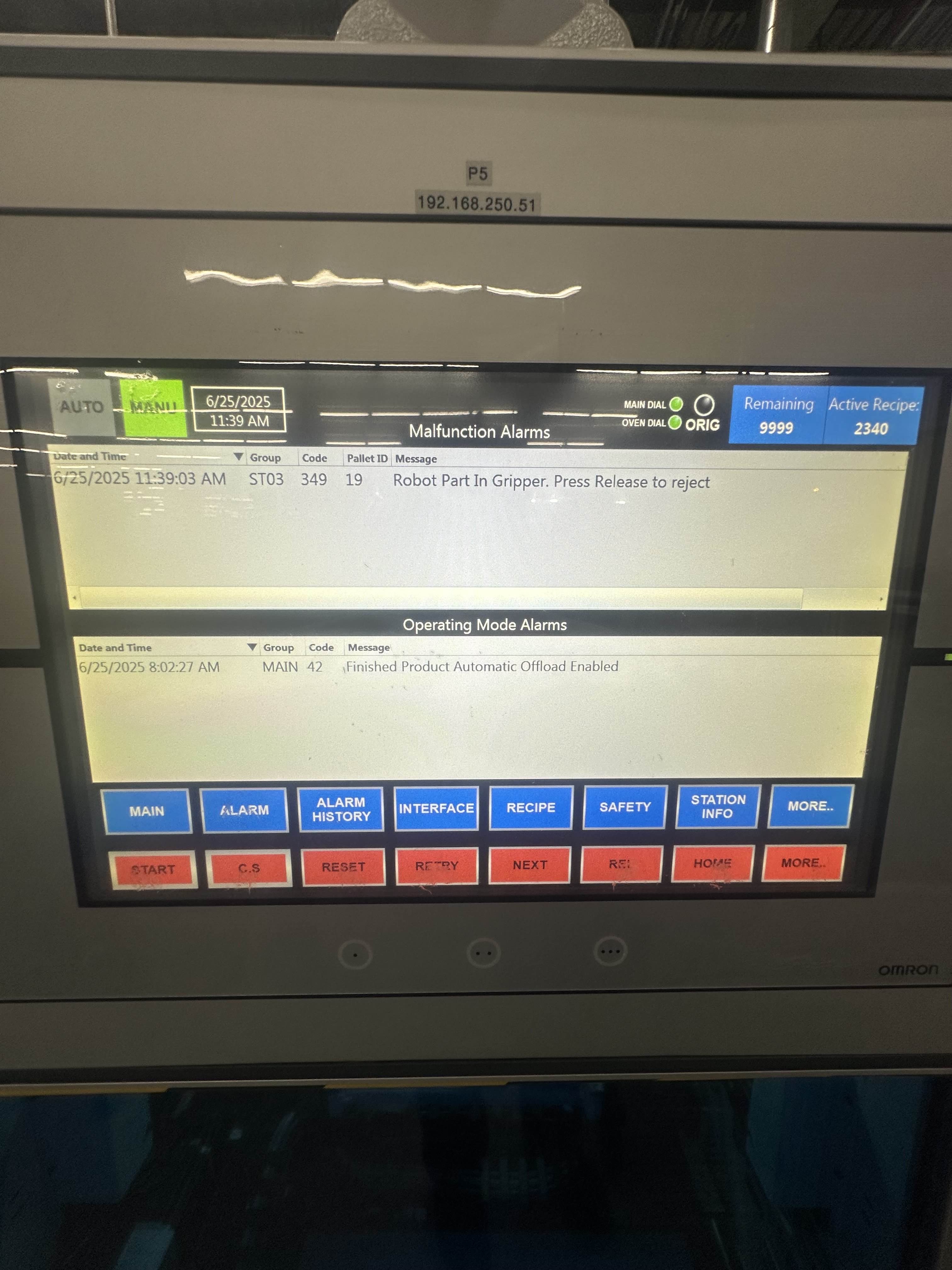

Optimized PLC control logic and parameters on high-volume automotive production lines at Veoneer to improve cycle time, stability, and run-rate consistency. Actively tuned live control logic without disrupting operations and helped design a revamped HMI for new production lines, improving alarm clarity, operating mode visibility, and operator interaction during changeovers and fault recovery.

Project Visuals

Technologies Used

PLC ProgrammingMATLABStatistical AnalysisCPK AnalysisGage R&R

Key Features

- PLC parameter tuning and logic optimization for cycle-time improvement

- Revamped HMI design for new production lines

- Improved alarm visibility and operating mode clarity

- Live production tuning without disrupting operations

- Enhanced operator interaction during changeovers and fault recovery

Challenges

- Optimizing cycle time while maintaining process stability

- Making PLC changes on live, high-volume production lines

- Designing HMIs that are intuitive for operators under time pressure

- Balancing automation efficiency with human interaction constraints

Outcomes

- Improved cycle time through targeted PLC parameter optimization

- Delivered a revamped HMI adopted on new production lines

- Reduced operator ambiguity during alarms and changeovers

- Improved production stability and smoother line launches