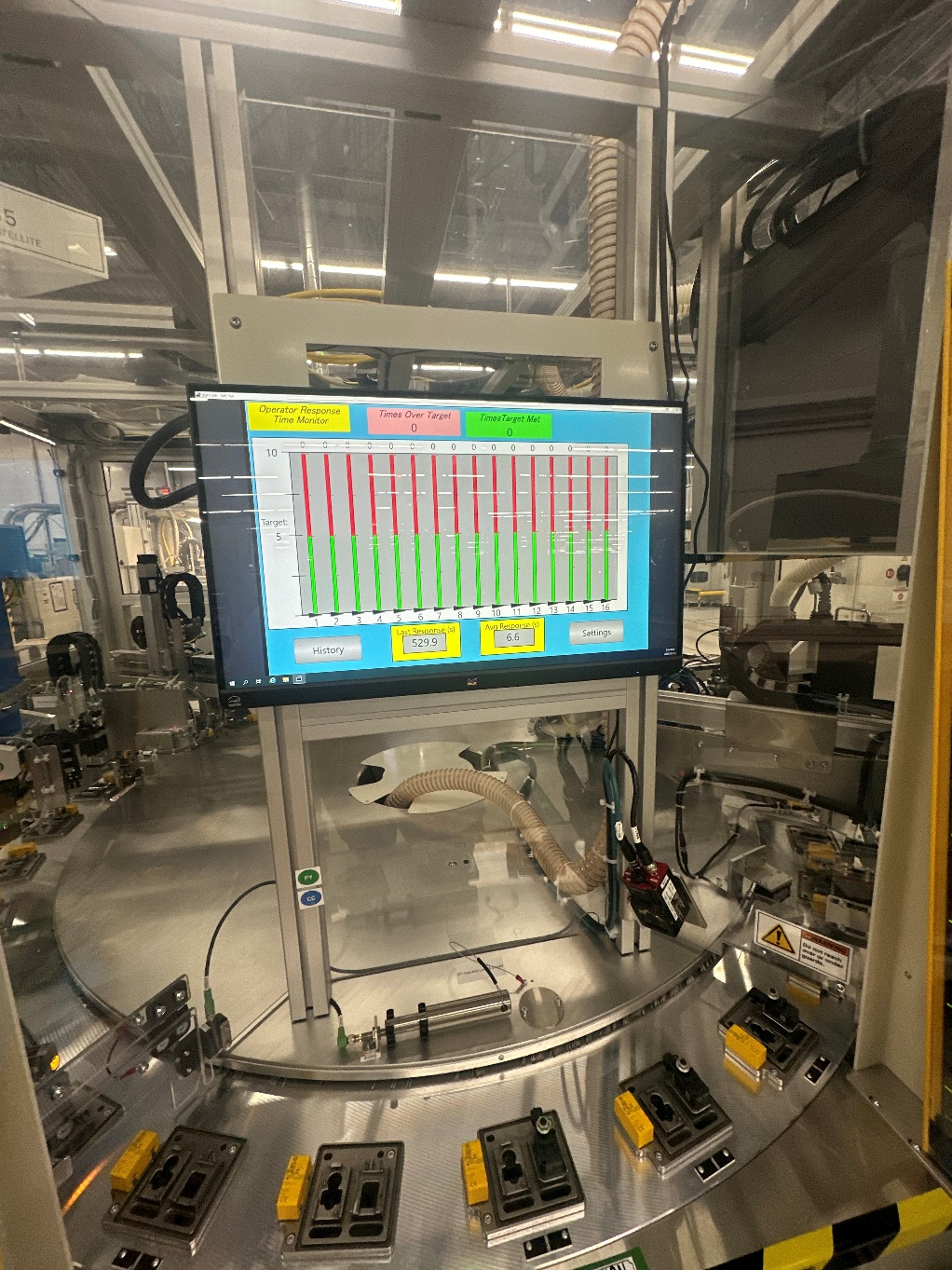

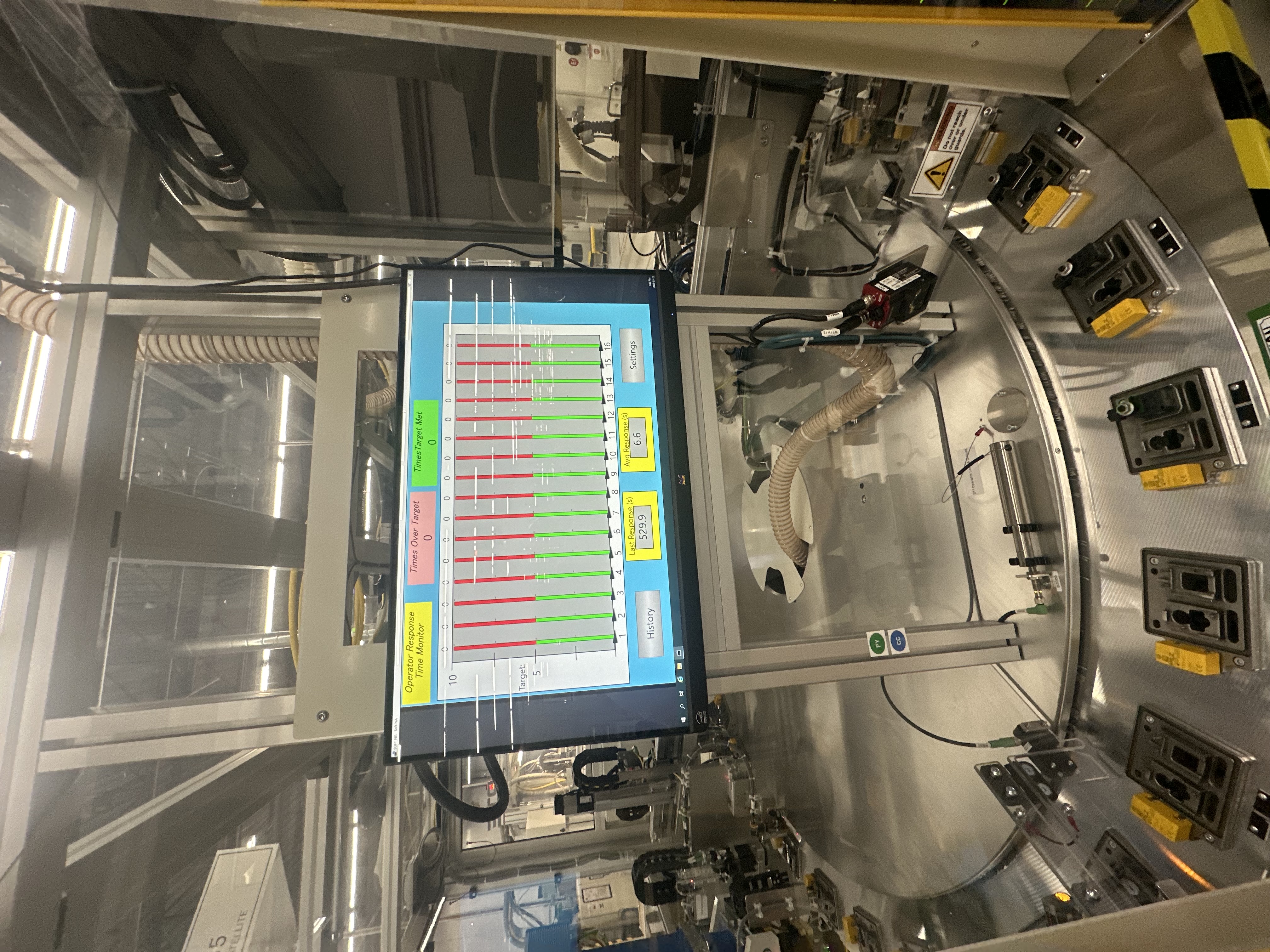

Operator Response Monitoring System

Developed an operator response monitoring system for a high-volume automotive production line at Veoneer to reduce human-induced delays during manual changeover steps. The system objectively measured the time required for an operator to remove a completed part and install a new housing—providing cycle-time visibility for a process that was previously unmonitored. Implementation was achieved by integrating directly into existing OMRON PLC control logic using Sysmac Studio, extending live machine state tracking with timing and state-based logic without disrupting normal operations. A real-time HMI visualization was designed to display response times against target thresholds, historical trends, and over-target events, enabling engineers and operators to identify bottlenecks and performance deviations across shifts. The solution proved highly successful and was subsequently deployed across every production line in the plant, standardizing operator response measurement and enabling data-driven process optimization at scale.

Project Visuals

Technologies Used

Key Features

- Real-time operator response time measurement

- PLC-integrated state and timing logic

- Non-intrusive integration into live production systems

- Real-time HMI visualization with thresholds and alerts

- Historical trend tracking across shifts

Challenges

- Integrating into existing PLC logic without disrupting production

- Accurately isolating operator response time from machine cycle time

- Designing intuitive HMI visuals for both operators and engineers

Outcomes

- Converted operator response from an implicit assumption into a measurable signal

- Enabled identification of bottlenecks and performance deviations

- Deployed across every production line in the plant

- Supported standardized, data-driven process optimization at scale